In many areas, the demand to extend service life through refurbishing is a sign of the times and makes an important contribution to ensuring the sustainability of existing resources. Individual instances of damage to existing infrastructure do not necessarily mean the end of its service life. At the same time, cost-effective refurbishment is a key point in the refurbishment process for bridges, wind turbine components or entire rail vehicles, for example. Welded constructions predominate in all the industries mentioned. These connections also represent failure-critical points within the structure. The repair of cracks in the area of welded seams is often associated with considerable effort to prepare the crack site by gouging and preparing the weld, limited accessibility or the presence of operating loads during the repair.

For older constructions, there is also the problem of the weldability of old steels and thus the risk of hot cracks and lamellar fractures due to shrinkage stresses. These problems can be countered in many ways with "cold" joining technology. The use of blind fasteners is a promising alternative, especially when accessibility from one side is required. However, there are a number of questions associated with their use with regard to dimensioning and execution, which are currently being clarified individually through case-by-case studies.

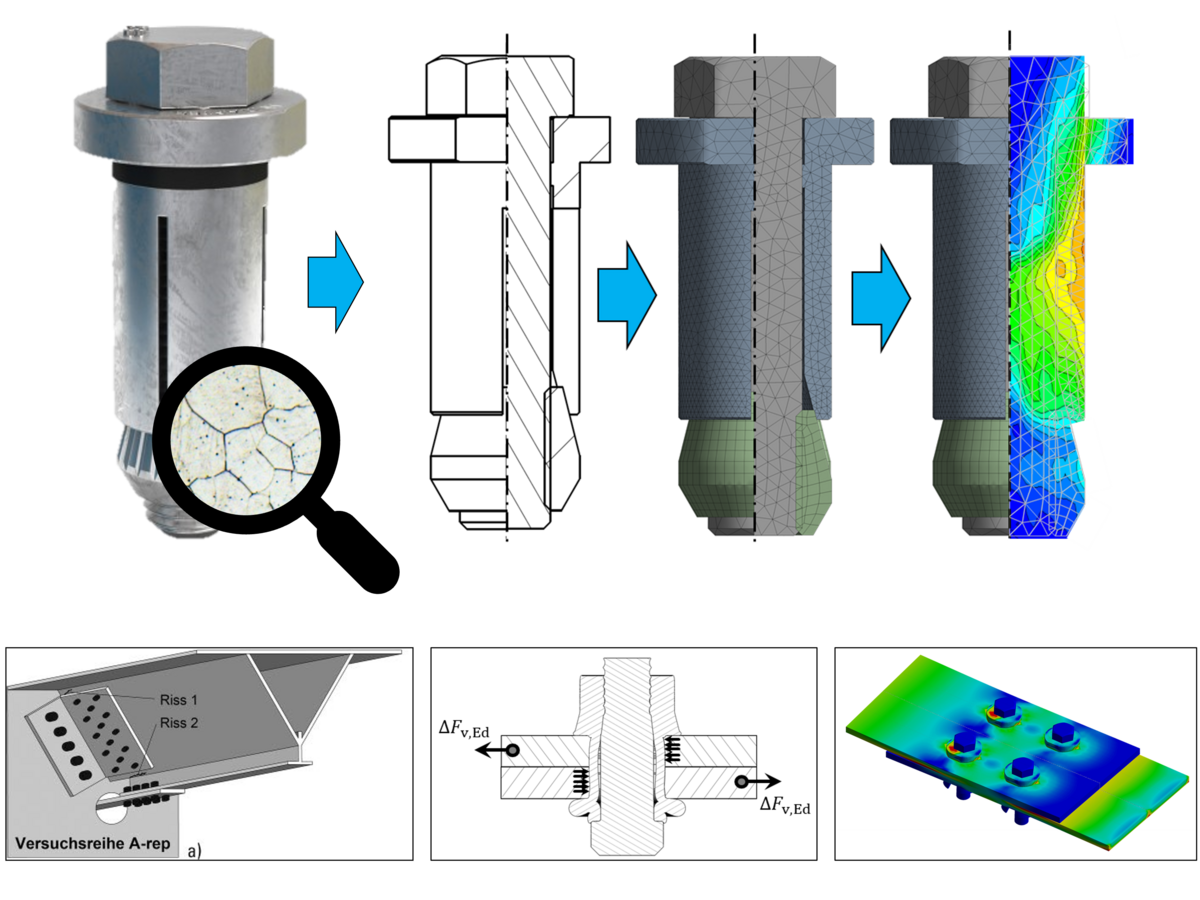

The aim of the research project is therefore to investigate the load-bearing behavior of mechanically joined connections with blind fasteners for the possibility of repair, but also for new product developments. To this end, topics such as hole filling capacity, the combination of positive and non-positive locking due to preload forces in connections, the load-bearing behavior under load reversal and repeated load action as well as the fatigue behavior under cyclic load action are to be considered.