Subproject "Development of a material design and novel gas-free processing technology for abrasive waterjet cutting of complex hollow structures in the deep sea"

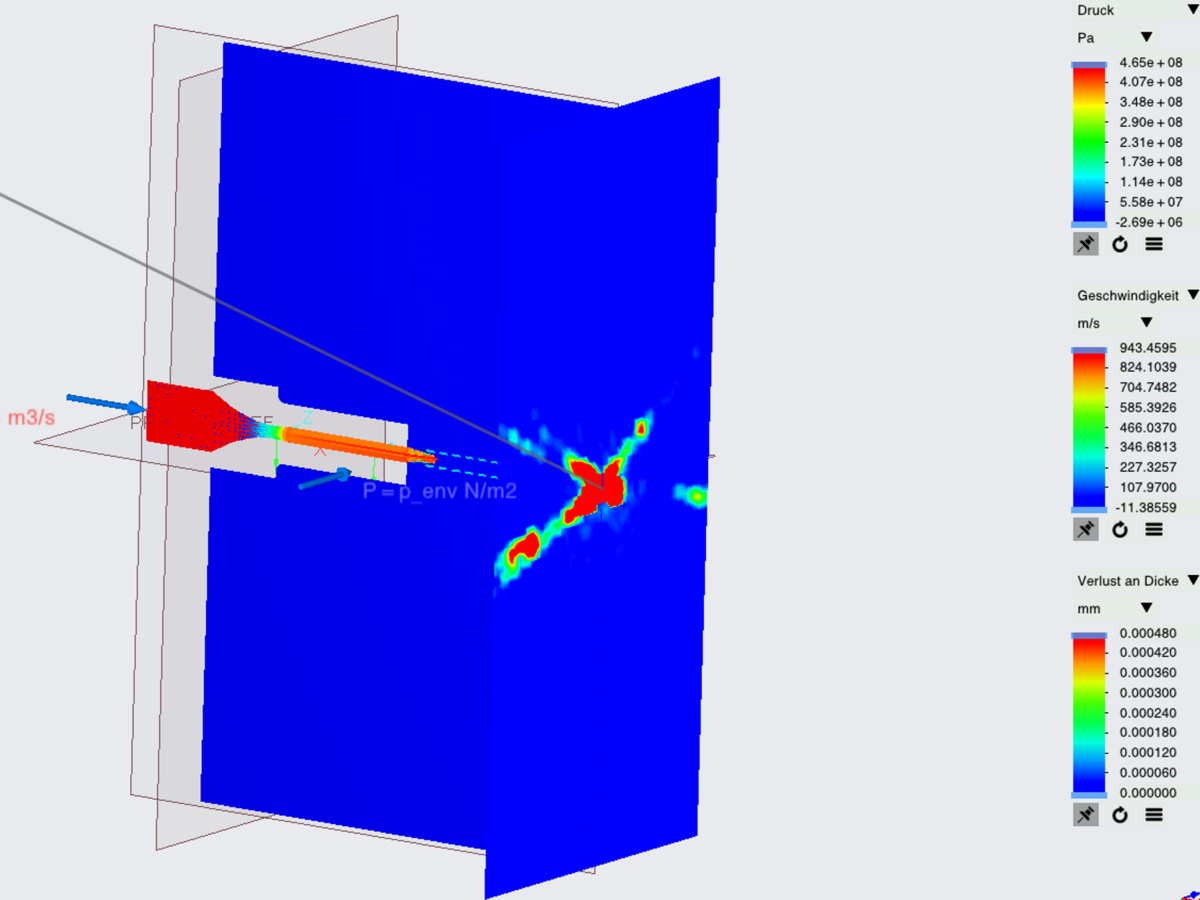

The aim of this joint project is to develop a periphery that will enable ANT AG to offer water jet cutting of complex geometries and hollow structures in water depths of up to t= 5 km. The development of a new type of nozzle forms the basis for the gas-free processing of complex hollow structures at water depths of up to t=5 km. By using a numerical prediction model, the machining process of complex hollow structures can be planned before execution, which considerably shortens the machining time on the ship and thus reduces costs. Process technology is being developed for real-time control of the machining process and short-term adaptation of the parameters to the prevailing environment using technology tables. With the help of a new, intelligent nozzle head, gas-free processing of complex hollow structures at high water depths will be realized. Finally, endurance tests are carried out to validate the overall system and optimize the machining process using the developed demonstrator.