The research project in the field of building materials technology, together with the industrial partner H + H Kalksandstein GmbH, Kavelsdorf plant, pursues two main goals:

- The further development of the well-known masonry building material sand-lime brick for sustainable construction by using reusable production residues or recycling materials from deconstruction. For this purpose, formulations and processes are developed, the hydrothermally produced samples are tested for their application properties and optimised in this regard.

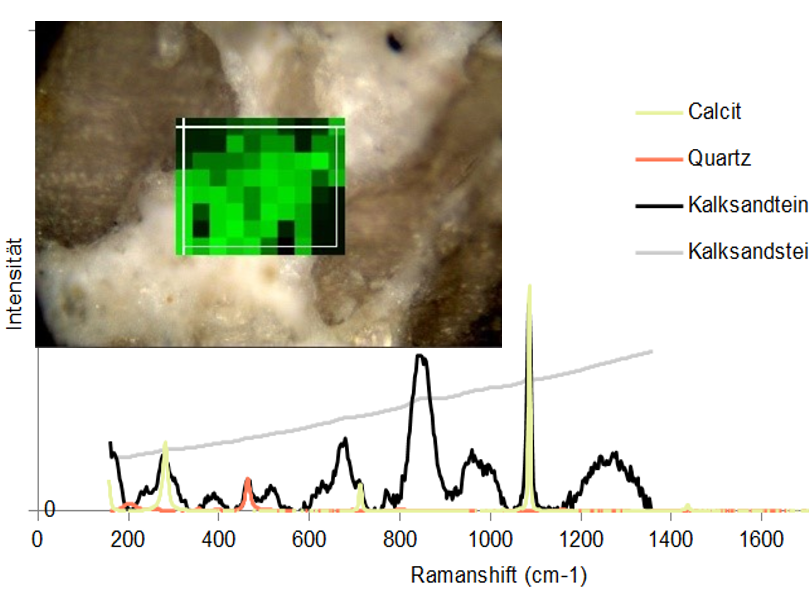

- The qualification of Raman spectroscopy as a method of in-situ process analysis has not yet been introduced in sand-lime brick production. For this purpose, in addition to a laboratory autoclave, a specially manufactured autoclave chamber is used at the X-ray diffractometer of the department, which allows the continuous performance of analyses for the permanent monitoring of the chemical-mineralogical reaction processes during the hydrothermal hardening process lasting several hours, both by means of X-ray diffraction and, in parallel, by means of Raman spectroscopy via a glass fibre-coupled probe. As an instrumental-analytical method, Raman spectroscopy offers the possibility of recording and controlling the autoclave process as a central step in the industrial production of sand-lime bricks, more precisely than before by measuring pressure and temperature alone. This is of particular importance in view of the increased complexity of the raw material mix due to the use of recycled materials.