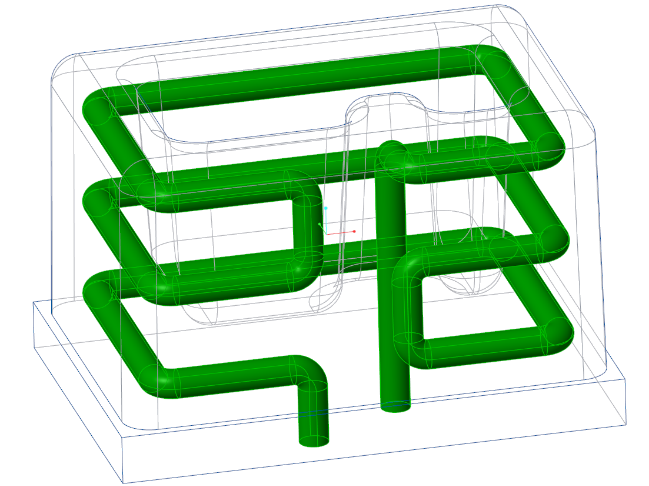

By means of FEM calculation, the topology / structure of the cooling channels as well as the necessary gradient curves are made visible in advance and made available as output within the framework of digital product development for manufacturing. For the creation of a complex cooling system close to the contour, which enables a turbulent flow of the coolant (Re>10,000), manufacturing technology has been developed in which additive manufacturing processes, such as DED processes, are combined with conventional manufacturing processes (milling/spark erosion).

By combining cooling channels close to the contour with the use of multi-material materials, moulds can be optimally designed thermally, whereby a uniform temperature (DeltaT<5°C) can be achieved on cavity surfaces.

The realised innovation product leads to the reduction of manufacturing costs by reducing the production time and enables a higher quality / imaging accuracy (<0.01mm).

As part of the sub-project, Wismar University of Applied Sciences is researching the material behaviour (thermal conductivity, mechanical strength, crack formation) of the combined materials developed by Kiel University of Applied Sciences by means of metallographies investigations using macrosections and microsections, thus identifying the optimum multi-material materials. Furthermore, the mechanical properties of the additively manufactured moulded component are proven with regard to strength, elongation at break, and hardness to avoid a static failure of the components by means of mechanical tests (tensile test, hardness test, notched bar impact test). Finally, the printed, optimised cavities and their plastic moulded components are measured and the surface qualities (Ra 0.03-0.5µm) are examined with the aid of modern 3D measuring technology such as computer tomography, tactile measurements (probe size 0.5-3mm) and optical 3D measuring systems.