In general, the verification of fatigue strength is always necessary where components or structures experience cyclic loads in the duration of their service life. The verification of fatigue strength in the field of steel construction is carried out according to the ∆σ-concept and represents a powerful verification method, especially for the design practice in engineering consultants, but also for iterative design in the field of supporting structures for wind turbines or bridge structures made of steel. The safe application of the nominal stress concept in turn requires a secured resistance value in the form of a detail category for a corresponding construction detail, in which all influencing variables from component design and stress level as well as design-side influencing variables (including edge processing, hole and edge distances in bolted connections) are included. This represents a reliable procedure for many welded components.

For bolted connections or components with holes, there are also detail categories according to DIN EN 1993-1-9, which must be applied reliably, but partly conservatively. Own current research results show corresponding potential according to the ∆σ-concept of Eurocode 3. In the course of the planned research project, a series of non-welded construction details are to be investigated, which should serve to develop a corresponding further development of the verification of fatigue strength according to Eurocode 3. The modification concerns both the Wöhler line slope and the consideration of the strength of the sheet materials for non-welded components and connections with mechanical fasteners according to Tab. 8.1 of DIN EN 1993-1-9. However, this is to be carried out under the aspect of production and assembly practice in steel construction.

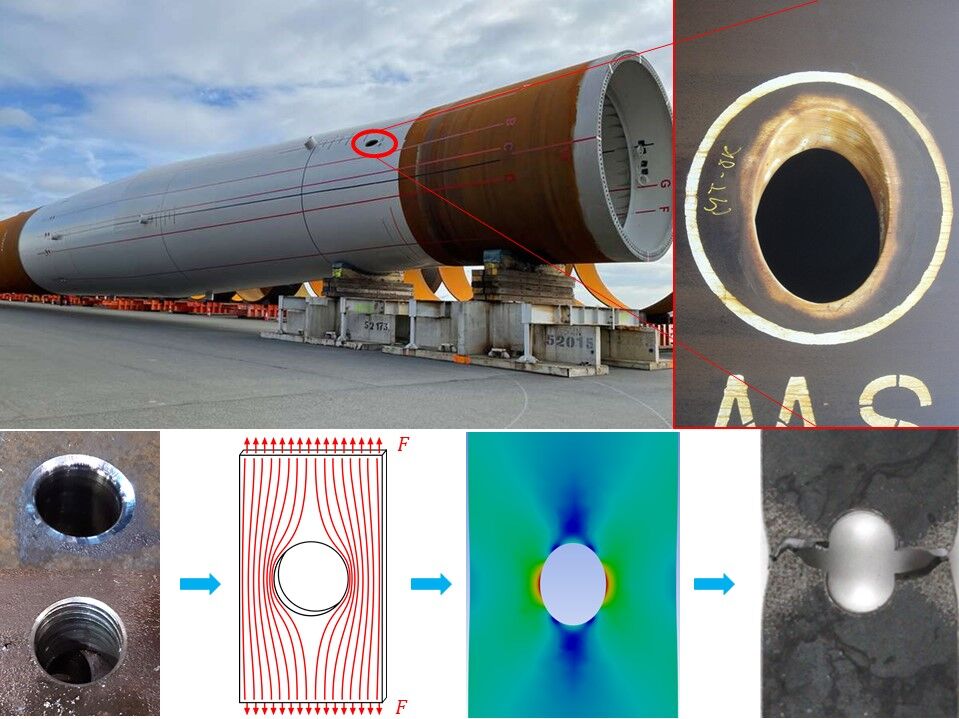

Cover image sources:

- Tower: www.industr.com/de/erste-xxl-monopiles-stechen-in-see-2645672

- Right detail image of hole: www.subenesol.co.uk/Products/SUB-BUNG-OWF-S-Subsea-Diver-Installed-Bungs

- Pictures below left (hole & thread): Ralf Glienke (private)

- Picture with line of force: https://de.wikipedia.org/wiki/Schwingfestigkeit#/media/Datei:HoleForceLines.svg

- Picture numerics:: Markus Schröder, Wismar University of Applied Sciences

- Picture broken hole bar: Markus Schröder, Wismar University of Applied Sciences