The safe and economical design of mechanically joined connections is of great importance to companies due to the multiplier effect. In mechanical and plant engineering, the transverse forces occurring in a bolted connection must be transmitted by frictional locking in accordance with VDI 2230-1. Both the clamping force and the coefficient of static friction are included in the slip safety verification.

Since the coefficient of static friction can vary greatly depending on the design, only conservative values or ranges are specified in regulations. In the case of coated components, experimental investigations often have to be carried out. For the aforementioned industry, these can be carried out in accordance with EN 1090-2, whereby the procedure is geared towards steel construction and does not take into account the geometric diversity or complex load history in mechanical engineering.

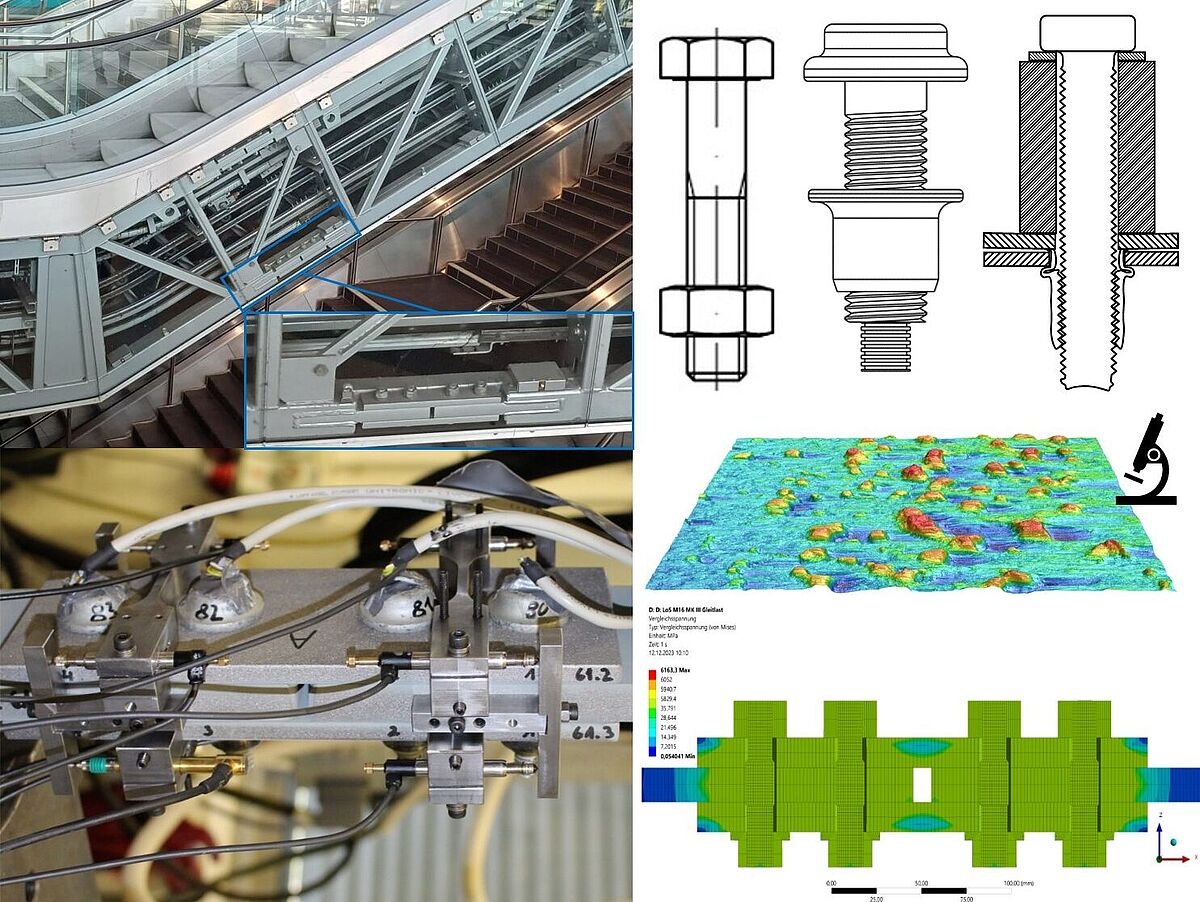

Therefore, this project aims to develop a test procedure for determining the coefficient of static friction, taking into account the application-specific influencing factors of the connection. To this end, the coefficient of static friction is first determined on samples subjected to transverse forces using TBJ and TTJ. For a better understanding of the mechanisms, the surfaces are characterized and the pressure state is analyzed using FEM. The transferability of the results to more complex connections will be carried out using FEM and validated with corresponding experimental investigations. Among other things, different types of loads, load histories, connecting elements, and friction surface pretreatments will be investigated.

Based on the findings, taking into account the relevant influencing factors, an efficient test procedure for determining the static friction coefficient on small test specimens and a catalog of measures for optimization are derived, which in particular will save SMEs the trouble of developing individual test concepts in the future and enable the transferability of the results.