In mechanical engineering, the proof of the fatigue strength at th endurance limit is an essential design criterion. The bolted joint is of great importance in design practice due to its good assembly and disassembly properties. Consequently, the state of knowledge on the behaviour of bolted joints with fasteners made of carbon steel is comprehensive. However, this must be classified as insufficient with regard to the verification of the fatigue strength of bolted joints made of stainless steel.

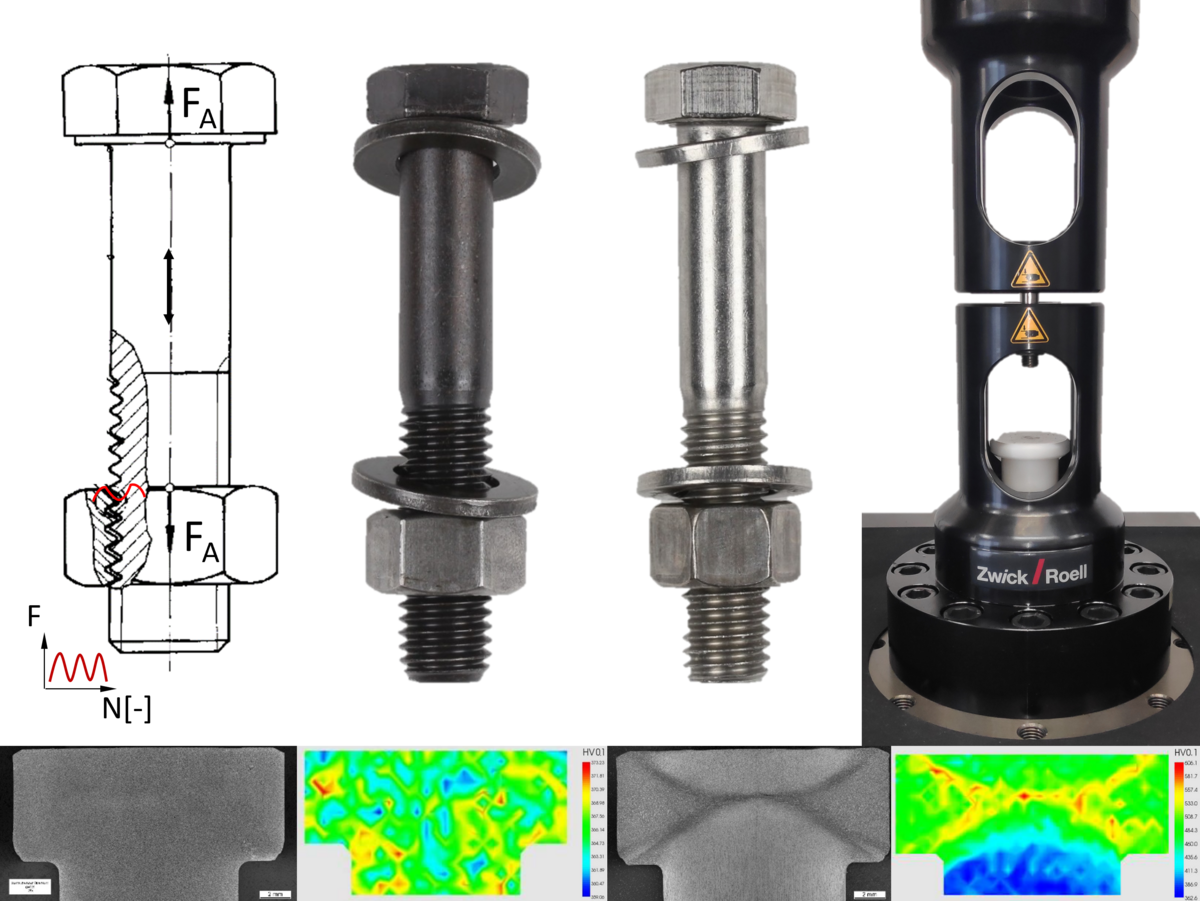

The axial fatigue strength, in particular the endurance limit of bolt-nut-joints made of stainless steel compared to bolts made of carbon steel, is only supported to a limited extent by experimental studies. As a result, the fatigue strength of stainless bolts is not included in the current standards. This leads to uncertainties in the design of bolted joints with bolts made of stainless steel when applying existing regulations, such as VDI 2230 - Part 1, especially in the endurance limit.

The aim of the research project is to investigate the axial fatigue strength in the finite life region and at the endurance limit of bolt-nut-joints made of stainless steel with regard to the effect of size, strength and mean stress as well as the effect of the steel group (austenitic, ferritic, martensitic and austenitic-ferritic). Furthermore, a comprehensive characterisation of the mechanical-technological properties and the effect of common bonded coatings and liquid lubricants on fatigue strength will be investigated. The verification of the fatigue strength of axially loaded bolted joints for the fatigue and fatigue-resistant design will be formulated on the basis of statistical analyses in accordance with the VDI 2230 - Part 1. This will be defined in relation to the slope parameter and the knee point of the S-N curve, as well as an endurance limit or a second slope parameter of the S-N curve without a significant endurance limit.